Discover how drones for asset inspection revolutionize industrial maintenance by providing safer, faster, and cost-effective solutions with advanced sensors, precise data collection, and strategic implementation methods.

Industrial asset inspection has transformed dramatically over the past decade. Traditional methods involving scaffolding, rope access, and expensive shutdowns are giving way to more efficient alternatives. Drones equipped with advanced sensors and specialized tools now offer unprecedented access to hard-to-reach structures while maintaining safety standards.

This technological shift isn't just about convenience – it represents a fundamental change in how companies approach preventive maintenance and regulatory compliance. Asset-heavy industries like oil and gas, power generation, and manufacturing are discovering that aerial inspection platforms can deliver superior data quality at a fraction of traditional costs.

Table of contents

- How drone asset inspection works

- Key benefits of using drones for inspections

- Common drone inspection applications

- Types of drone sensors and equipment

- Choosing the right drone platform

- Implementation strategies and best practices

- Cost analysis and ROI considerations

- Regulatory compliance and safety protocols

- Getting started with drone inspections

How drone asset inspection works

The inspection process begins long before the drone takes flight. Mission planning involves studying the asset, identifying potential hazards, and selecting appropriate equipment. Weather conditions, airspace restrictions, and electromagnetic interference all factor into flight preparation.

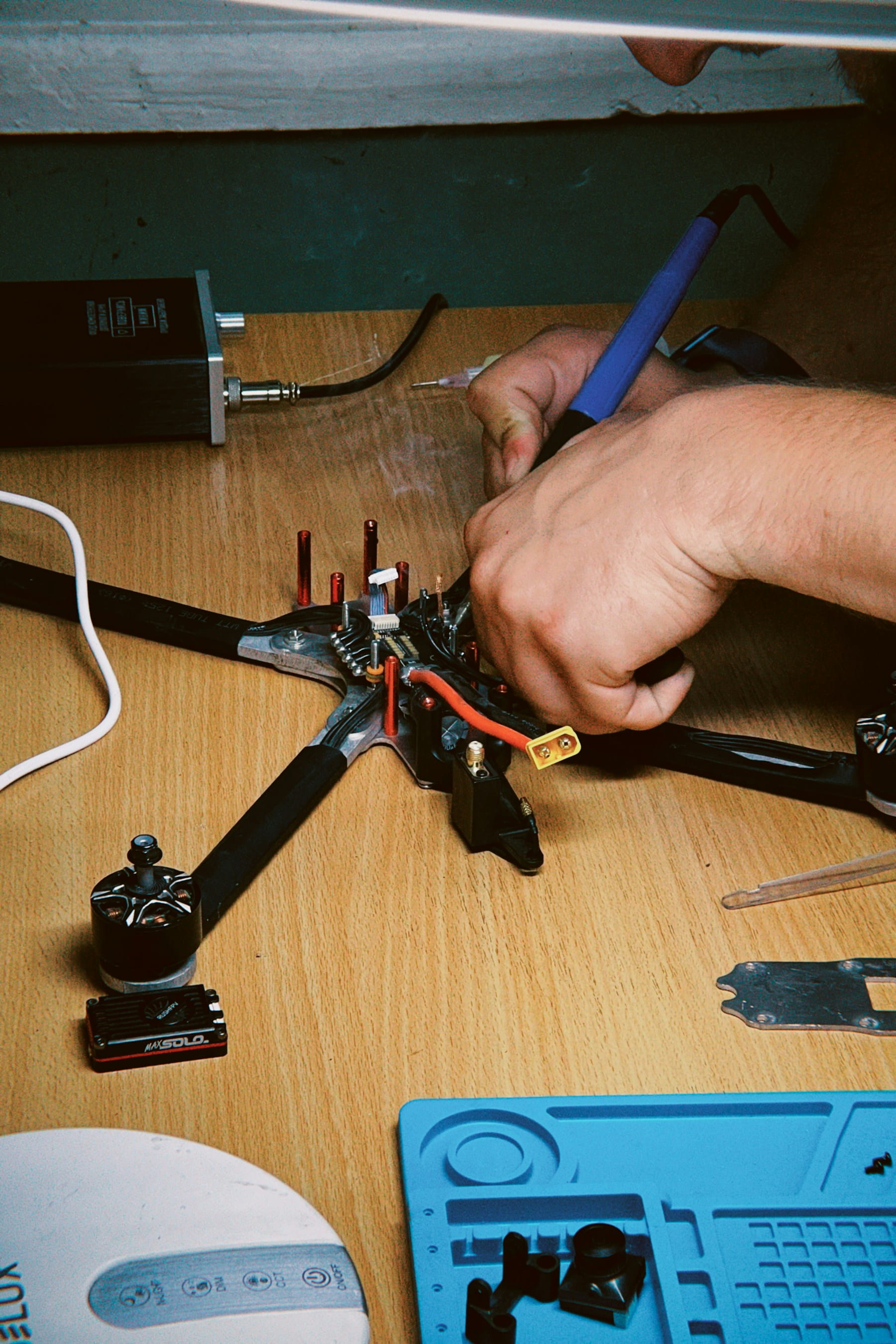

Modern inspection drones carry multiple sensor packages simultaneously. A typical setup might include high-resolution cameras, thermal imaging sensors, and LiDAR systems. Some platforms can also mount specialized tools for non-destructive testing, allowing direct contact with structural surfaces.

Pre-flight preparation

Site assessment forms the foundation of successful drone inspections. Operators examine the target structure, noting obstacles like power lines, communication towers, or moving machinery. They also identify optimal vantage points and plan multiple takeoff locations if needed.

Flight path planning software has become increasingly sophisticated. These tools generate waypoints automatically based on the asset's geometry and inspection requirements. Pilots can simulate entire missions beforehand, identifying potential collision risks and optimizing data collection routes using systematic pre-flight procedures.

Equipment preparation involves more than just checking battery levels. Sensor calibration, payload balancing, and communication system testing all require attention following comprehensive maintenance protocols. A malfunctioning thermal camera or unstable gimbal can compromise an entire inspection mission.

Data collection process

Flight operations typically require minimal crew – often just one certified pilot and a safety observer. The drone follows pre-programmed routes while operators monitor live feeds and adjust parameters in real-time. Advanced obstacle avoidance systems allow closer approach to complex structures than previously possible.

Data capture happens at multiple levels. Visual cameras record high-definition video and still images. Thermal sensors detect temperature variations that might indicate equipment failure or structural issues. LiDAR systems create precise 3D models for dimensional analysis.

Contact-based measurements add another layer of capability. Specialized drones can actually touch surfaces to perform ultrasonic thickness testing, coating measurements, and electrical continuity checks. This bridges the gap between remote sensing and traditional hands-on inspection methods.

Post-flight analysis

Raw data processing transforms sensor readings into actionable information. Photogrammetry software converts image sequences into detailed 3D models. Thermal analysis algorithms identify hotspots and temperature gradients. Artificial intelligence systems can automatically detect cracks, corrosion, and other anomalies.

Report generation has become largely automated. Software platforms compile inspection findings into standardized formats that meet regulatory requirements. Historical data comparison helps track asset degradation over time, supporting predictive maintenance strategies.

Key benefits of using drones for inspections

Speed represents perhaps the most obvious advantage. What once took days or weeks can now be completed in hours. A storage tank inspection that previously required scaffolding construction and multiple technicians can be finished with a single pilot in one afternoon.

Safety improvements extend beyond eliminating fall risks. Drone inspections can proceed during normal operations, avoiding the hazards associated with confined space entry or proximity to moving equipment. Workers no longer need to approach high-voltage electrical systems or climb chemical processing towers.

Cost reduction factors

Direct cost savings come from eliminating expensive access equipment. No more scaffolding rentals, crane services, or specialized lifting platforms. The equipment costs alone can exceed the price of a complete drone inspection program.

Labor efficiency multiplies these savings. Traditional inspections often require large crews with specialized skills. Drone operations typically need just one or two trained personnel, freeing other staff for productive work.

Operational downtime represents another significant cost factor. Many assets must be shut down for conventional inspections, causing lost production and revenue. Drones can often inspect equipment while it remains in service, minimizing business disruption.

Data quality improvements

Modern sensors capture far more information than human inspectors can observe directly. Thermal cameras detect temperature variations invisible to the naked eye. High-resolution photography reveals surface details that might be missed during visual inspections.

Documentation consistency improves dramatically with drone-based inspections. Every surface gets recorded with precise GPS coordinates and timestamps. This creates comprehensive archives that support regulatory compliance and trend analysis.

Repeatability becomes possible when inspections follow identical flight paths. Asset degradation tracking requires consistent measurement points and viewing angles. Automated flight systems can reproduce exact inspection procedures years later.

Common drone inspection applications

Industrial applications span virtually every sector with significant physical assets. Power generation facilities use drones to inspect cooling towers, boilers, and transmission equipment. Oil and gas operations survey pipelines, storage tanks, and offshore platforms.

Infrastructure inspections

Bridge assessments represent one of the fastest-growing applications. Drones can access bridge undersides and structural elements that would otherwise require expensive access equipment. Detailed photography and thermal imaging help identify concrete deterioration, steel corrosion, and joint problems.

Cell tower inspections have become routine for many telecommunications companies. Drones check antenna positioning, structural integrity, and equipment condition without requiring technicians to climb dangerous heights. The process takes hours instead of days and eliminates fall risks entirely.

Wind turbine blade inspections showcase drone capabilities particularly well. These massive structures present unique access challenges for traditional methods. Drones can approach blades from multiple angles, capturing high-resolution images of leading edges, trailing edges, and root connections.

Industrial facility assessments

Chemical plants and refineries present complex inspection challenges. Multiple structures, hazardous materials, and active processes create dangerous environments for human inspectors. Drones can safely navigate these facilities while equipment remains operational.

Storage tank inspections have become a specialty application. External surface assessments check for corrosion, coating degradation, and structural damage. Internal inspections can proceed while tanks remain partially filled, avoiding costly product removal and cleaning procedures.

Flare stack examinations demonstrate the unique capabilities of specialized drone platforms. These high-temperature structures operate continuously and cannot be safely approached by conventional means. Heat-resistant drones can collect visual and thermal data while stacks remain operational.

Specialized inspection types

Gas leak detection relies on sophisticated sensor packages. Optical gas imaging cameras can visualize methane, hydrogen sulfide, and other invisible gases. These inspections help prevent environmental releases and workplace hazards while supporting regulatory compliance.

Coating thickness measurements traditionally required direct surface contact with handheld gauges. Drone-mounted instruments can now perform these measurements at height, checking protective coatings on bridges, towers, and industrial equipment.

Lightning protection system testing presents unique technical challenges. These systems require electrical continuity verification, which traditionally meant sending technicians onto exposed structures during favorable weather conditions. Specialized drones can now perform these tests safely and efficiently.

Types of drone sensors and equipment

Visual imaging systems form the backbone of most inspection operations. Modern cameras offer 4K video recording, mechanical gimbal stabilization, and zoom capabilities exceeding 100x magnification. These systems can capture surface details from safe distances while maintaining image quality.

Thermal imaging technology

Infrared sensors detect heat patterns that indicate equipment problems. Electrical connections generate excess heat before failure. Bearing wear creates friction and temperature rises. Insulation defects allow heat transfer in unexpected patterns.

Thermal data requires careful interpretation. Environmental factors like wind, solar heating, and reflective surfaces can influence readings. Experienced thermographers understand how to compensate for these variables and identify genuine anomalies.

Quantitative temperature measurement adds precision to thermal inspections. Calibrated sensors can measure absolute temperatures with accuracy approaching laboratory instruments. This enables trend tracking and threshold-based alerting systems.

Advanced sensing capabilities

LiDAR systems create precise 3D models of inspected structures. These point clouds support dimensional analysis, clearance verification, and change detection over time. Survey-grade accuracy enables engineering-level measurements from aerial platforms.

Ultrasonic testing equipment allows thickness measurements through drone-mounted probes. Specialized platforms can maintain stable contact with surfaces while applying appropriate pressure for accurate readings. This technology bridges the gap between remote sensing and traditional contact-based inspection methods.

Gas detection sensors range from simple electrochemical cells to sophisticated laser spectrometers. Selection depends on target gases, sensitivity requirements, and environmental conditions. Some systems can identify and quantify multiple gas species simultaneously.

Emerging technologies

Artificial intelligence integration is transforming data analysis. Machine learning algorithms can identify crack patterns, corrosion types, and equipment anomalies automatically. These systems learn from human expertise and improve accuracy over time.

Multispectral imaging extends beyond visible light into near-infrared and other wavelengths. This technology can detect material properties invisible to conventional cameras, including moisture content, coating composition, and vegetation health.

Ground-penetrating radar and electromagnetic sensors are being miniaturized for drone deployment. These technologies enable subsurface inspection capabilities that complement traditional visual and thermal methods.

Choosing the right drone platform

Platform selection depends heavily on inspection requirements and operating conditions. Large industrial sites might benefit from long-endurance platforms with extended communication ranges. Confined spaces require compact, agile designs with superior obstacle avoidance capabilities.

Size and payload considerations

Payload capacity determines sensor options and flight duration. Heavy thermal cameras and LiDAR systems require substantial lifting capability. Specialized testing equipment adds weight and may affect flight stability.

Battery life directly impacts operational efficiency. Frequent battery changes interrupt workflow and limit coverage area. Cold weather and heavy payloads reduce flight time significantly, requiring careful mission planning.

Weather resistance varies dramatically between platforms. Industrial environments often involve dust, moisture, and temperature extremes. Some applications require operation in light rain or snow, while others demand resistance to chemical vapors.

Mobility and access capabilities

Standard multirotor designs excel in open environments but struggle near complex structures. Omnidirectional platforms can approach surfaces from any angle, enabling contact-based measurements on vertical and overhead surfaces.

Indoor capabilities require GPS-independent navigation systems. Visual-inertial odometry and LiDAR-based simultaneous localization and mapping (SLAM) enable operation in confined spaces without satellite signals.

Automated flight modes reduce pilot workload and improve data consistency. Waypoint navigation, object tracking, and pre-programmed inspection patterns help standardize procedures across different operators and locations.

Communication and control systems

Radio range limitations can restrict inspection areas, particularly around large industrial facilities with electromagnetic interference. Long-range systems or mesh networking capabilities may be necessary for comprehensive coverage.

Real-time data streaming allows immediate decision-making during flights. Live thermal feeds can guide pilots to areas requiring closer examination. Ground-based analysis software can process data streams and provide instant feedback.

Beyond visual line of sight operations require special equipment and regulatory approval. These capabilities enable inspection of extended infrastructure like pipelines and transmission lines but involve additional complexity and compliance requirements.

Implementation strategies and best practices

Successful drone inspection programs require more than just purchasing equipment. Staff training, procedure development, and integration with existing maintenance systems all contribute to program effectiveness.

Building internal capabilities

Pilot certification represents the first step in developing internal capabilities. Commercial drone operations require specific licenses and ongoing training through comprehensive UAS pilot programs. Multiple certified operators provide operational flexibility and backup coverage.

Technical training extends beyond basic flight skills. Sensor operation, data analysis, and safety procedures require specialized knowledge. Some organizations partner with equipment manufacturers for comprehensive training programs.

Maintenance competency becomes important as programs mature. Basic troubleshooting, calibration procedures, and preventive maintenance help minimize downtime and ensure data quality. Service agreements can supplement internal capabilities.

Integration with existing systems

Asset management integration connects inspection findings with maintenance planning systems. Automated data transfer reduces manual work and improves response times. Condition-based maintenance strategies benefit from regular drone inspection data.

Quality management systems may require updates to accommodate drone-generated documentation. Inspection procedures, data validation protocols, and record retention policies need revision to reflect new capabilities.

Regulatory compliance frameworks must address drone-specific requirements. Aviation regulations, data privacy laws, and industry-specific standards may apply to drone inspection operations, requiring thorough understanding of compliance management.

Operational procedures

Standard operating procedures ensure consistent results across different operators and locations. Flight planning protocols, safety checklists, and emergency procedures help maintain operational safety and data quality.

Documentation requirements vary by industry and application. Some inspections must meet specific regulatory standards for report format and content. Automated reporting systems can help ensure compliance while reducing manual effort.

Continuous improvement processes help optimize drone inspection programs over time. Regular procedure reviews, equipment evaluations, and operator feedback contribute to program effectiveness and cost reduction.

Cost analysis and ROI considerations

Initial equipment costs vary widely based on platform selection and sensor requirements. Professional-grade inspection drones range from tens of thousands to hundreds of thousands of dollars. However, these costs often pale compared to traditional access equipment expenses for major inspections.

Direct cost comparisons

Scaffolding construction for large storage tanks can exceed $100,000 before any inspection work begins. Crane rentals for tower inspections cost thousands per day. Rope access specialists command premium hourly rates and require extensive safety support.

Drone inspections eliminate most access-related expenses. A comprehensive storage tank inspection might cost 10-20% of traditional methods when including data collection, analysis, and reporting. The savings multiply for assets requiring frequent monitoring.

Labor efficiency improvements compound these direct savings. Traditional inspections often require large crews with diverse specializations. Drone operations typically need just one or two trained personnel, reducing coordination complexity and scheduling conflicts.

Indirect benefits

Reduced downtime prevents lost production and revenue. Many assets must shut down completely for conventional inspections. Drone inspections often proceed during normal operations, maintaining productivity while gathering necessary data.

Safety improvements have measurable value through reduced insurance costs and accident prevention. Eliminating high-risk activities like confined space entry and work at height reduces both direct costs and regulatory exposure.

Data quality improvements support better maintenance decisions. More frequent inspections enable condition-based maintenance strategies that optimize equipment life and prevent unexpected failures. The value of avoiding unplanned outages often exceeds inspection costs many times over.

Long-term considerations

Technology evolution continues to improve drone capabilities while reducing costs. New sensors, longer flight times, and enhanced automation provide increasing value over time. Early adopters often see their ROI improve as technology advances.

Training investments develop internal capabilities that support multiple applications. Pilots trained for one type of inspection can often adapt to others with minimal additional education. This flexibility maximizes the value of human resource investments.

Scalability advantages become apparent as programs mature. Additional assets can be added to inspection schedules with minimal incremental cost. Large organizations often find that drone programs become more cost-effective as they expand across multiple facilities.

Regulatory compliance and safety protocols

Aviation regulations govern drone operations in most jurisdictions. Commercial inspections typically require operator certification, aircraft registration, and adherence to specific operating rules. Understanding regulatory compliance ensures all requirements are met. These requirements vary by country and may include flight restrictions near airports or populated areas.

Operational limitations

Weight restrictions affect equipment selection and operational capabilities. Many jurisdictions have different rules for drones above and below specific weight thresholds. Heavier inspection platforms may face additional regulatory requirements or operating restrictions.

Altitude limitations can impact inspection procedures for tall structures. Maximum operating heights vary by location and may require special authorization for operations near airports or in controlled airspace.

Beyond visual line of sight operations require special approvals in most jurisdictions. Extended pipeline or transmission line inspections may need these capabilities but involve additional regulatory complexity and equipment requirements.

Safety management systems

Risk assessment procedures help identify potential hazards before operations begin. Site surveys, weather evaluations, and equipment inspections all contribute to operational safety. Documented risk management processes demonstrate due diligence to regulators and stakeholders.

Emergency procedures address equipment failures, communication loss, and other contingencies. Pilot training must cover emergency response protocols including forced landings, flyaway situations, and medical emergencies.

Insurance considerations vary based on operation type and potential liability exposure. Aviation insurance, professional liability coverage, and equipment protection all merit evaluation. Some clients require specific insurance levels or coverage types.

Documentation requirements

Flight records must be maintained for regulatory compliance and operational analysis. Pilot logbooks, maintenance records, and incident reports help demonstrate adherence to safety protocols and support continuous improvement efforts.

Inspection documentation standards vary by industry and application. Some sectors require specific report formats or data retention periods. Quality management systems may need updates to address drone-generated documentation requirements.

Privacy considerations become important when operating near populated areas or sensitive facilities. Data handling protocols, access controls, and retention policies help address privacy concerns while maintaining operational effectiveness.

Getting started with drone inspections

The path to implementing drone inspections starts with understanding specific needs and constraints. Asset types, inspection requirements, and operational environment all influence platform selection and program development.

Market research helps identify suitable equipment and service providers. Industry publications, trade shows, and peer organizations provide valuable insights into proven solutions and emerging technologies. Pilot programs can validate concepts before major investments.

Pilot program development

Small-scale testing allows evaluation of drone capabilities without major financial commitment. Single-asset inspections or specific use cases provide learning opportunities while demonstrating potential value to stakeholders.

Service provider partnerships can accelerate initial implementation. Experienced contractors bring specialized equipment, trained personnel, and proven procedures. These relationships provide immediate capability while internal programs develop.

Success metrics should be established before beginning pilot programs. Cost comparisons, data quality assessments, and operational efficiency measurements help quantify benefits and guide program expansion decisions.

Scaling considerations

Equipment standardization simplifies training, maintenance, and operational procedures. Multiple drone types may be necessary for different applications, but minimizing variety reduces complexity and costs.

Staff development represents a critical success factor. Pilot training, technical education, and procedure development all require ongoing investment. Some organizations establish centers of excellence to support multiple facilities or business units.

Vendor relationships become increasingly important as programs mature. Equipment suppliers, software providers, and service contractors all contribute to program success. Strategic partnerships can provide competitive advantages and cost reductions.

Why Industrial Asset Inspection Drones Matter for Modern Operations

Managing industrial asset inspections with drone technology requires comprehensive operational systems that integrate safety protocols, regulatory compliance, and data management. Professional operators who implement systematic inspection programs gain significant operational advantages while maintaining the highest safety and quality standards through continuous flight data monitoring.

- Safety transformation: Drone inspections eliminate high-risk activities while providing superior data quality

- Operational efficiency: Faster inspections with minimal downtime reduce costs and improve asset availability

- Regulatory confidence: Comprehensive documentation ensures compliance with industry standards and regulations

- Predictive maintenance: Regular drone data enables condition-based maintenance strategies and failure prevention

Getting Started with Professional Asset Inspections

- Assess inspection requirements and identify critical assets for drone deployment

- Select appropriate platforms balancing sensor capabilities with operational requirements

- Implement training programs following certified pilot standards

- Establish maintenance protocols ensuring equipment reliability

- Develop compliance frameworks addressing regulatory requirements

Essential preparation: Before deploying asset inspection drones, ensure your operational framework addresses safety protocols, data management, and integration with existing maintenance management systems.

In Summary

Drone inspection platforms offer unprecedented opportunities to improve asset management while reducing costs and safety risks. The technology has matured beyond experimental applications to become a proven tool for industrial maintenance and compliance. Success requires careful planning, appropriate equipment selection, and ongoing commitment to safety and quality.

Ready to Transform Your Asset Inspection Capabilities?

Join industrial operators who have revolutionized their maintenance programs through advanced drone inspection systems and comprehensive operational management. Whether you're monitoring critical infrastructure, conducting routine assessments, or ensuring regulatory compliance, sophisticated inspection technologies enable operational excellence and predictive maintenance strategies.

Start your free trial today — no credit card required.

Or book a demo to see how DroneBundle integrates asset inspection workflows with compliance management, maintenance tracking, and performance analytics in a platform designed specifically for professional industrial operations.

Transform your maintenance capabilities into competitive advantages. With comprehensive drone inspection systems and professional operational support, every assessment becomes an opportunity to demonstrate technical expertise and deliver superior asset management outcomes.