What is Drone Equipment Management?

Drone equipment management is a systematic approach to tracking, maintaining, and allocating all physical and digital assets used in drone operations—including aircraft, batteries, sensors, controllers, software licenses, and pilot certifications—to ensure operational efficiency, regulatory compliance, and equipment reliability through centralized tracking systems and standardized procedures.

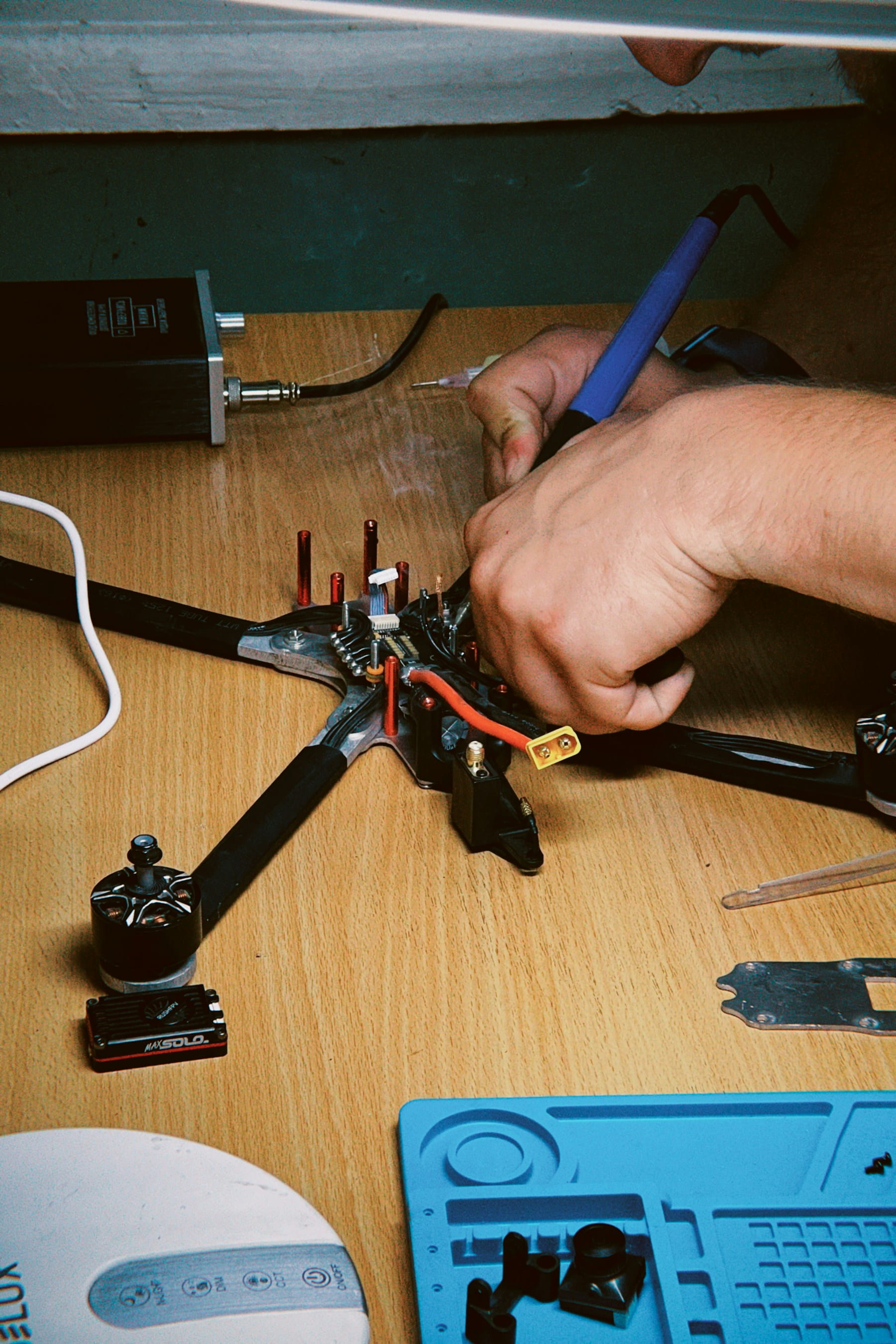

Professional drone operations require more than just skilled pilots and quality aircraft. Behind every successful commercial drone program lies a sophisticated equipment management system that tracks everything from battery health to certification expiry dates. This operational backbone determines whether teams can scale efficiently or struggle with unexpected downtime and compliance issues.

Equipment management in drone operations encompasses far more than basic inventory tracking. Teams must monitor pilot certification currency across multiple pilots, coordinate complex equipment bundles for different mission types, and maintain detailed records for regulatory compliance. The challenge grows exponentially as operations scale from single-pilot teams to enterprise-level fleet management operations managing dozens of aircraft and hundreds of accessories.

Modern drone programs face increasing pressure to optimize operations while maintaining strict safety standards. Equipment failures during critical missions can result in costly delays, while certification lapses can ground entire teams. Successful programs implement systematic approaches that transform equipment management from a reactive burden into a strategic advantage.

Table of contents

- Core components of drone equipment management

- Building effective equipment tracking systems

- Managing pilot certifications and compliance

- Equipment assignment and allocation strategies

- Creating standardized equipment bundles

- Battery management and power systems

- Maintenance scheduling and lifecycle tracking

- Safety equipment and regulatory compliance

- Technology solutions for equipment management

- Best practices for scaling operations

- Common challenges and solutions

- Frequently Asked Questions

Core components of drone equipment management

Professional drone operations depend on multiple interconnected equipment categories. Each requires specific management approaches and tracking protocols.

Aircraft themselves represent just one component of comprehensive equipment inventories. Controllers, batteries, chargers, sensors, and specialized payloads all require individual attention. Landing pads, safety equipment, and transportation cases add additional layers of complexity.

The equipment ecosystem extends beyond physical hardware. Software licenses, cloud storage allocations, and data processing capabilities all require management oversight. Teams often overlook these digital assets until license renewals or storage limits create operational disruptions.

Physical equipment categories

Primary aircraft components form the foundation of equipment inventories. Drone frames, propellers, gimbals, and cameras require individual tracking with serial numbers, purchase dates, and maintenance histories. Controllers and remote transmitters need firmware version tracking and pairing records.

Power systems demand particular attention. Batteries degrade over time and usage cycles, making condition monitoring critical for flight safety. Chargers, power supplies, and field charging solutions require compatibility tracking and safety certifications.

Payload equipment varies significantly by mission type. Survey operations require precision cameras and GPS receivers. Inspection missions need thermal imaging sensors and zoom lenses. Each payload type brings unique calibration requirements and environmental considerations.

Support equipment often gets overlooked but plays critical roles. Landing pads protect aircraft during takeoffs and landings. Transportation cases prevent damage during transit. Spare parts inventories enable rapid repairs and minimize downtime.

Digital assets and software

Software components require systematic tracking just like physical equipment. Flight planning applications, data processing software, and cloud services all have licensing terms and renewal dates. Teams must monitor user counts, feature access, and subscription tiers.

Firmware versions across aircraft, controllers, and payloads need coordination. Mismatched versions can cause compatibility issues or limit functionality. Update schedules should align with operational requirements and regulatory approvals.

Data storage and processing capabilities represent increasingly important assets. Cloud storage quotas, processing credits, and bandwidth allocations all impact operational capacity. Teams must balance cost management with performance requirements.

Building effective equipment tracking systems

Successful equipment management starts with comprehensive tracking systems that provide real-time visibility into equipment status, location, and condition. These systems must accommodate diverse equipment types while remaining user-friendly for field personnel.

Basic spreadsheet approaches quickly become inadequate as operations scale. Manual entry creates opportunities for errors, while static databases fail to provide real-time updates. Modern operations require dynamic systems that integrate with operational workflows.

Equipment identification forms the foundation of any tracking system. Unique identifiers, whether serial numbers, asset tags, or QR codes, must be consistently applied and maintained. Standardized naming conventions prevent confusion and enable efficient searching.

Location tracking and assignment

Equipment location tracking prevents loss and enables efficient allocation. Simple check-in/check-out systems work for small teams, while larger operations require more sophisticated approaches. GPS tracking devices can monitor high-value equipment automatically.

Assignment protocols should balance flexibility with accountability. Equipment may be assigned to specific pilots, projects, or locations depending on operational needs. Clear assignment records prevent conflicts and enable rapid equipment location.

Mobile access becomes increasingly important as teams work in distributed locations. Field personnel need the ability to check equipment status, report issues, and update assignments without returning to office locations. Cloud-based systems enable real-time synchronization across multiple users.

Condition monitoring and alerts

Equipment condition tracking extends beyond simple working/broken classifications. Battery cycle counts, flight hours, and environmental exposure all impact equipment reliability. Systematic condition monitoring enables proactive maintenance and replacement decisions. Flight data monitoring provides insights into equipment performance and usage patterns.

Automated alerts can flag equipment approaching service intervals, certification expiry dates, or usage limits. These notifications should reach relevant personnel with sufficient advance warning to arrange maintenance or replacements without disrupting operations.

Historical tracking provides valuable insights for equipment lifecycle management. Usage patterns, failure modes, and repair costs help inform future purchasing decisions and maintenance strategies. This data becomes increasingly valuable as operations mature.

Managing pilot certifications and compliance

Pilot certification management represents one of the most critical aspects of drone equipment management. Expired certifications can ground operations instantly, while improper assignment of uncertified pilots creates significant legal liabilities.

Part 107 certifications require renewal every 24 months through recurrent training. Teams must track individual expiry dates and plan renewal schedules well in advance. Last-minute renewals can create operational disruptions if training slots are unavailable. Comprehensive pilot training programs ensure team members maintain current certifications.

Specialized certifications add complexity to tracking requirements. Night operations, extended visual line of sight, and specific payload endorsements all have unique requirements and validity periods. Mission assignment systems must verify pilot qualifications before approving flight operations. Systematic tracking of pilot flight hours helps ensure experience requirements are met.

Certification tracking systems

Centralized certification databases provide visibility into pilot qualifications across entire operations. These systems should track multiple certification types, endorsements, and training completions for each pilot. Automated renewal reminders help prevent lapses.

Document management becomes critical for regulatory compliance. Digital copies of certificates, medical clearances, and training records must be readily accessible. Version control ensures teams always reference current documents rather than outdated copies.

Integration with mission planning systems enables automatic qualification verification. Pilots should only see mission assignments matching their certifications and endorsements. This integration prevents assignment errors and maintains compliance automatically.

Training and professional development

Ongoing training programs keep pilots current with regulatory changes and operational best practices. Training schedules should align with certification requirements while accommodating operational demands. Regular assessments verify skill maintenance and identify areas needing attention.

Professional development opportunities help retain skilled pilots while expanding operational capabilities. Advanced training courses following ASTM F3266 standards, manufacturer certifications, and industry conferences all contribute to pilot competency. Training investments should align with operational growth plans.

Documentation of training activities supports regulatory compliance and professional development goals. Training records should include course content, completion dates, and assessment results. This documentation proves valuable during regulatory audits and insurance reviews.

Equipment assignment and allocation strategies

Effective equipment assignment balances operational efficiency with equipment utilization and accountability. Different assignment strategies work better for different operational models and team structures.

Personal assignment models give individual pilots responsibility for specific equipment sets. This approach works well for smaller teams where pilots specialize in particular mission types. Personal assignment creates strong accountability but can limit equipment utilization.

Pool assignment strategies maximize equipment utilization by allowing flexible allocation based on mission requirements. Central equipment pools work well for larger teams with diverse mission profiles. Pool systems require stronger tracking and control processes to maintain accountability.

Project-based allocation

Project assignment models allocate equipment to specific contracts or operational areas, enabling accurate cost tracking for long-term deployments. Pre-configured bundles for common project types—survey cameras with GPS, inspection thermal sensors—streamline assignment processes. Geographic strategies use regional equipment caches to reduce transportation costs while ensuring local availability.

Dynamic allocation systems

Advanced allocation systems consider multiple factors: pilot qualifications, mission requirements, equipment condition, and availability. Automated systems optimize assignments for efficiency and compliance while handling real-time adjustments for equipment failures or mission changes.

Conflict resolution uses priority systems for critical missions, reservation systems for planned operations, and clear escalation procedures when automated solutions fall short.

Creating standardized equipment bundles

Equipment bundles simplify mission preparation while ensuring consistent capability delivery. Standard bundles reduce setup time, minimize missing equipment issues, and enable efficient inventory management.

Mission type drives bundle configuration requirements. Survey operations require different equipment combinations than inspection missions or emergency response deployments. Bundle standardization should reflect actual operational patterns rather than theoretical possibilities.

Bundle management requires careful balance between standardization and flexibility. Overly rigid bundles may not accommodate specific mission requirements, while excessive customization eliminates standardization benefits. Successful programs develop core bundles with defined customization options.

Bundle design principles

Core equipment identification forms the foundation of bundle design. Primary aircraft, essential controllers, and critical payloads represent non-negotiable bundle components. Optional components can be added based on specific mission requirements.

Redundancy considerations influence bundle composition. Critical missions may require backup equipment for essential components. Redundancy decisions should balance risk mitigation with cost and complexity considerations. Not every mission requires full redundancy.

Transportation and setup efficiency should guide bundle organization. Equipment should pack efficiently in standard cases while remaining readily accessible during field operations. Logical grouping reduces setup time and minimizes forgotten components.

Bundle management workflows

Bundle assembly procedures using checklists ensure consistent configuration and reduce preparation errors. Quality control processes verify component functionality, battery charge levels, and software updates before deployment.

Post-mission procedures handle cleaning, charging, and basic maintenance during bundle disassembly, with damaged components flagged for repair.

Battery management and power systems

Battery management represents one of the most critical aspects of drone equipment management. Battery failures can cause aircraft crashes, while degraded batteries reduce operational capability and create safety risks.

Lithium polymer batteries commonly used in professional drones have specific storage, charging, and usage requirements. Temperature extremes, deep discharge cycles, and physical damage all accelerate battery degradation. Systematic battery management extends service life while maintaining safety.

Cycle count tracking provides the most reliable indicator of battery condition. Most professional drone batteries support 200-500 charge cycles before significant capacity loss occurs, with modern batteries meeting UN38.3 and IEC 62133 safety standards for lithium battery transport and safety. Teams must balance cycle counting with practical operational requirements.

Battery lifecycle management

New battery break-in procedures optimize long-term performance. Initial charging cycles should follow manufacturer recommendations to ensure proper cell balancing. Documentation of initial capacity measurements provides baseline performance references.

Storage procedures significantly impact battery longevity. Long-term storage requires partial charge levels and temperature-controlled environments. Storage charge monitoring prevents deep discharge damage during extended periods between uses.

Retirement criteria should be established before batteries reach unsafe conditions. Capacity thresholds, cycle count limits, and physical condition assessments all contribute to retirement decisions. Clear retirement procedures prevent degraded batteries from remaining in service.

Charging infrastructure and procedures

Charging station design must accommodate multiple battery types while maintaining safety standards. Dedicated charging areas with appropriate ventilation and fire suppression reduce risks. Charging schedules should align with operational requirements while avoiding rushed charging procedures.

Charge cycle documentation tracks individual battery usage and performance trends. Charging logs should record charge times, capacity measurements, and any abnormal conditions. This data supports lifecycle management and replacement planning.

Field charging capabilities enable extended operations away from base facilities. Portable charging solutions must balance capacity with portability while maintaining safety standards. Field charging procedures should account for environmental conditions and power source limitations.

Maintenance scheduling and lifecycle tracking

Proactive maintenance programs prevent equipment failures while optimizing lifecycle costs. Systematic maintenance scheduling balances preventive care with operational availability requirements.

Manufacturer maintenance schedules provide starting points for maintenance planning. Flight hour intervals, calendar periods, and cycle counts all trigger different maintenance requirements. Operational conditions may require more frequent maintenance than manufacturer recommendations.

Maintenance documentation supports regulatory compliance and warranty claims. Detailed records of maintenance activities, parts replacements, and performance tests demonstrate proper equipment care. Digital documentation systems enable efficient record keeping and retrieval.

Preventive maintenance programs

Inspection schedules identify potential issues before they cause failures. Visual inspections, functional tests, and performance measurements all contribute to condition assessment. Regular inspections should be documented and tracked systematically.

Component replacement schedules address wear items before failure occurs. Propellers, gimbals, and sensors all have predictable wear patterns. Scheduled replacement prevents unexpected failures during critical missions.

Calibration procedures ensure sensor accuracy and system integration. GPS receivers, cameras, and measurement sensors all require periodic calibration. Calibration schedules should align with accuracy requirements and operational demands.

Repair and overhaul management

Repair workflow management minimizes downtime while ensuring quality work. Rapid diagnosis, parts procurement, and repair scheduling all impact equipment availability. Standardized procedures improve efficiency and consistency.

Warranty management maximizes manufacturer support while minimizing costs. Warranty tracking, claim procedures, and authorized repair networks all require systematic management. Proper warranty utilization can significantly reduce maintenance costs.

Parts inventory management balances carrying costs with availability requirements. Common wear items should be stocked locally, while expensive components may require special ordering. Inventory levels should reflect usage patterns and lead times.

Safety equipment and regulatory compliance

Safety equipment management goes beyond personal protective equipment to encompass all systems and procedures that ensure safe operations. Regulatory compliance requires systematic tracking of equipment certifications, operational limitations, and documentation requirements.

Personal protective equipment varies by operational environment. Construction sites require different safety gear than maritime operations or agricultural applications. Safety equipment inventories must match operational exposure profiles.

Emergency equipment can be critical during accident response. Fire extinguishers, first aid supplies, and communication devices should be readily available during flight operations. Emergency equipment requires regular inspection and replacement to ensure reliability.

Regulatory compliance tracking

Equipment certification tracking ensures all equipment meets regulatory requirements. Aircraft registration, equipment approvals, and operational authorizations all require systematic monitoring. Compliance lapses can ground operations or create legal liabilities.

Documentation requirements vary by jurisdiction and operation type. Flight logs, maintenance records, and incident reports all require specific formats and retention periods. Digital documentation systems can automate compliance reporting and record keeping.

Audit preparation requires organized documentation and systematic record keeping. Regulatory audits can occur with minimal notice, making preparation an ongoing process rather than a reactive activity. Well-organized records demonstrate professional operation and regulatory compliance.

Incident response and equipment recovery

Incident response procedures must address equipment recovery and preservation. Accident scenes require careful documentation and evidence preservation. Equipment recovery procedures should balance investigative requirements with operational continuity needs.

Insurance coordination requires systematic documentation of equipment values, conditions, and incident circumstances. Insurance claims benefit from comprehensive records and proper equipment valuation. Regular equipment appraisals support accurate insurance coverage and claims processing.

Lessons learned processes should incorporate equipment-related incident findings into management procedures. Equipment modifications, procedure updates, and training improvements all contribute to continuous safety improvement. Incident analysis should drive systematic improvements rather than isolated corrections.

Technology solutions for equipment management

Modern equipment management relies heavily on software solutions that integrate tracking, scheduling, and reporting capabilities. Cloud-based platforms enable real-time access from multiple locations while maintaining centralized data integrity.

Mobile applications bring equipment management capabilities to field personnel. QR code scanning, condition reporting, and assignment updates can all be performed from smartphones or tablets. Mobile integration reduces data entry delays and improves accuracy.

Integration capabilities enable equipment management systems to work with other operational software. Flight planning platforms, accounting systems, and customer relationship management tools all benefit from equipment data integration. Seamless data flow eliminates duplicate entry and improves operational efficiency.

Software platform evaluation

Feature requirements should drive software selection. Core functionality includes equipment tracking, assignment management, and maintenance scheduling, with advanced features like automated alerts and mobile access adding operational value.

Scalability ensures systems grow with operations—user limits, equipment capacity, and performance should accommodate planned growth. Cost structures vary significantly, with total ownership including implementation, training, and ongoing support beyond licensing fees.

Implementation and training considerations

Implementation planning should address data migration, system configuration, and user training through phased rollouts that reduce disruption. Training programs must accommodate different skill levels for field personnel, administrators, and management.

Data security becomes critical as operations scale, requiring measures that protect equipment inventory values and sensitive operational data through robust access controls.

Best practices for scaling operations

Scaling drone operations creates exponential increases in equipment management complexity. Systems and procedures that work well for small teams often break down as operations grow beyond a few pilots and aircraft.

Standardization becomes increasingly important as operations scale. Equipment types, procedures, and documentation formats all benefit from standardization. Standard approaches reduce training requirements and improve operational consistency.

Delegation and responsibility distribution prevent single points of failure while improving operational efficiency. Clear roles and responsibilities enable systematic management without overwhelming individual team members. Delegation requires appropriate training and oversight procedures.

Organizational structure considerations

Equipment management roles should align with operational structure—small operations combine equipment management with other duties, while larger fleet operations require dedicated personnel. Geographic distribution necessitates regional equipment caches with local management, balanced against centralized oversight.

Vendor relationship management requires systematic approaches for volume purchasing, service agreements, and technical support as operations scale.

Process optimization strategies

Workflow automation reduces manual effort while improving consistency and accuracy. Routine tasks like inventory updates, maintenance reminders, and compliance tracking all benefit from automation. Automated systems free personnel for higher-value activities while reducing error rates.

Performance measurement enables continuous improvement and problem identification. Key metrics should address equipment utilization, maintenance costs, downtime frequency, and compliance rates. Regular performance reviews should drive systematic improvements.

Continuous improvement processes incorporate operational feedback into equipment management procedures. Field personnel often identify inefficiencies and improvement opportunities that management may miss. Formal feedback mechanisms ensure valuable insights drive systematic improvements.

Common challenges and solutions

Equipment management challenges often emerge gradually as operations scale and complexity increases. Recognizing common patterns enables proactive solutions rather than reactive problem solving.

Inventory accuracy deteriorates without systematic procedures and regular audits. Manual tracking systems become increasingly unreliable as equipment quantities and usage frequency increase. Regular physical inventories verify system accuracy and identify discrepancies.

Equipment conflicts arise when multiple teams require the same equipment simultaneously. Reservation systems and priority protocols can prevent conflicts, but require systematic implementation and user compliance. Clear escalation procedures resolve conflicts when automated systems fall short.

Budget and cost management

Equipment costs require systematic budgeting that addresses both immediate needs and long-term requirements. Hidden costs including training, maintenance, and insurance impact total ownership costs. Multi-year budget planning enables equipment refresh cycles without operational disruptions.

Personnel and training challenges

Skills gaps require training programs that address current needs while preparing for future requirements. Staff turnover impacts can be reduced through documentation, standardization, and knowledge transfer procedures. Recognition programs help maintain engagement in equipment management activities.

Frequently Asked Questions

How often should drone batteries be replaced?

Professional drone batteries typically need replacement after 200-500 charge cycles, depending on the battery type and usage conditions. However, replacement decisions should be based on multiple factors including capacity degradation (typically below 80% of original capacity), physical condition, and operational requirements. Teams should establish retirement criteria based on cycle counts, performance testing, and manufacturer recommendations rather than relying solely on calendar age.

What certifications must be tracked for commercial drone pilots?

Commercial drone operations require tracking Part 107 remote pilot certificates (renewed every 24 months), specialized endorsements for night operations or extended visual line of sight, and any manufacturer-specific payload certifications. Equipment management systems should also monitor training completion dates, medical clearances where required, and operational authorizations specific to certain mission types or geographic areas.

Do I need dedicated software for equipment management or can I use spreadsheets?

While spreadsheets work for small operations with one or two pilots, dedicated equipment management software becomes essential as teams scale beyond basic operations. Software platforms provide automated alerts for maintenance intervals and certification expiries, enable mobile access for field personnel, integrate with flight planning systems, and maintain audit trails for regulatory compliance. The transition from spreadsheets typically occurs when managing more than 5-10 aircraft or when coordination between multiple pilots becomes challenging.

Implementation Considerations

Effective equipment management requires integration of multiple operational elements. Organizations should start with core tracking capabilities and systematic maintenance protocols, building a foundation that expands as operations grow. Successful implementations begin with essential equipment inventories and basic compliance tracking before adding advanced features.

Teams managing multiple aircraft should prioritize integration between equipment management and broader operational platforms. Establishing robust management foundations early ensures systems can accommodate scaling growth without requiring complete replacement.

In Summary

Professional drone operations succeed through systematic equipment management that balances operational efficiency with regulatory compliance and safety requirements. The complexity of modern drone programs demands sophisticated management approaches that can scale with operational growth while maintaining high standards.

Equipment management extends far beyond simple inventory tracking to encompass lifecycle management, compliance monitoring, and strategic planning. Successful programs invest in systematic processes and technology solutions that enable scalable operations without compromising safety or efficiency.

The drone industry continues to evolve rapidly, bringing new challenges and opportunities to equipment management. Organizations that establish robust management foundations will be better positioned to adapt to technological advancement and regulatory changes while maintaining operational excellence.

Ready to Streamline Your Equipment Management?

Join professional operators who have transformed their equipment tracking through comprehensive management systems designed for commercial drone operations. Whether you're managing certification tracking, optimizing maintenance schedules, or coordinating fleet-wide equipment allocation, systematic equipment management enables operational excellence and regulatory confidence.

Start your free trial today — no credit card required.

Or book a demo to see how DroneBundle integrates comprehensive equipment management with fleet operations and maintenance scheduling in a platform designed specifically for professional drone operations.